Floor Leveling

Concrete floors are commonly installed in distribution centers, warehouse clubs, food and beverage manufacturing, retail centers, home centers, and many other commercial and industrial facilities. Concrete is a durable flooring choice. It can handle high traffic and the movement of machinery, forklifts, and other heavy equipment. A concrete floor that is sagging, not level, or uneven can cause damage to equipment and present a safety hazard to employees. It can also cause damage to racking systems and other business assets.

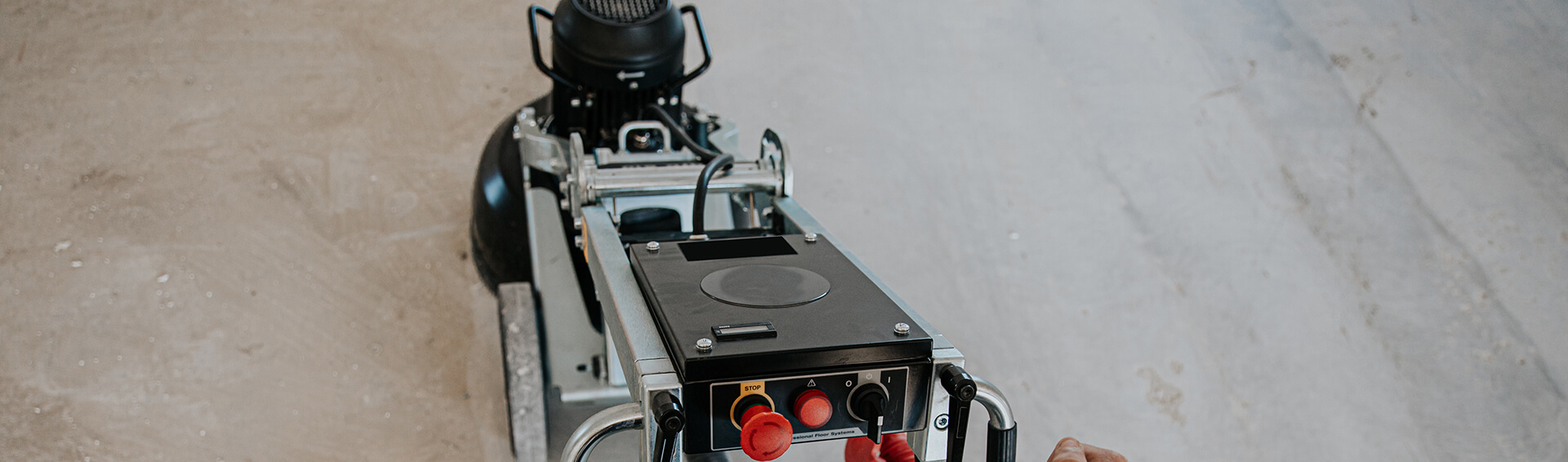

Concrete floors may become uneven for many reasons, and inconsistent moisture content is one of the primary causes. Many facilities have moisture problems due to faulty installation. Over time, the constant rising of the water can cause separation throughout the facility. Cracks, chips, or holes can appear when stressed by equipment movement. When Blair Duron inspects uneven or sagging floors, we generally recommend a self-leveling concrete flooring solution. This product combines a cement base with urethane polymers. It delivers a viscous material. The material will quickly spread evenly across your old surface, creating a new flat and even floor. The benefits of choosing this floor leveling process include:

- The unique chemical mixture can be poured over existing floor finishes. These include concrete, wood, vinyl, ceramic tile, plywood, and other hard surfaces.

- It is easy to install, does not require facility construction or heavy preparation before installing the new material, and has minimal installation time.

- You can choose to leave the finish in natural cement color, add a top coat for sealing the finish, or customize it with stains, pigments or decorative broadcast.

- It is strong, has low permeability, offers sound reduction (STC), and resists moisture, thermal shock, and chemical spills.